This Unique Bridge is Rational in a Particular Context.

Oklahoma Turnpike Authority

Road construction is typically noisy, prolonged, and results in traffic congestion at all times of the day. While it's impossible to completely eliminate the noise or shorten the duration of a project, there are strategies to reduce delays. One approach is to use a dedicated overpass to transport construction materials over the affected roads. Recently, a concrete conveyor belt bridge was set up over Interstate 44 in Oklahoma.

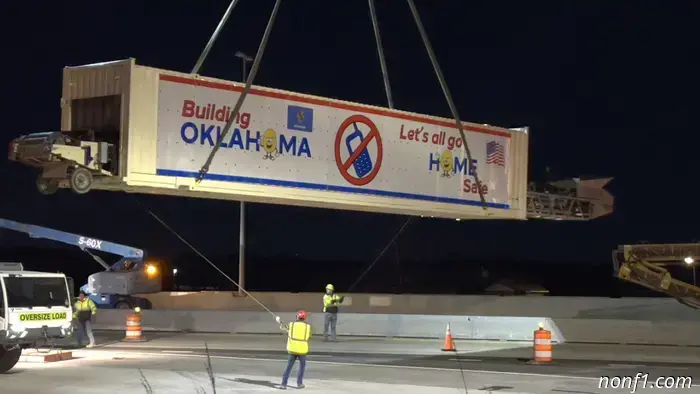

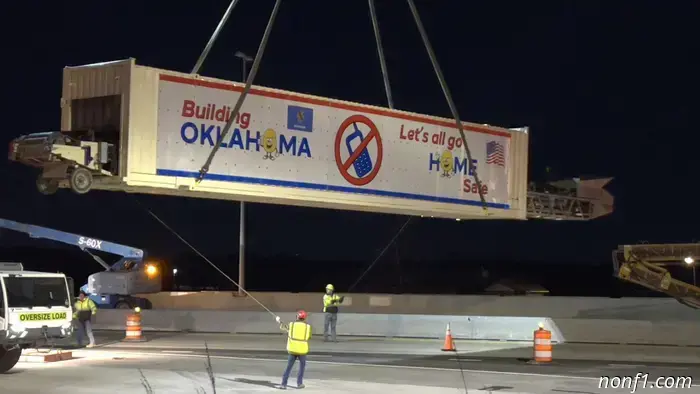

As part of a highway expansion effort, construction partner Duit Construction implemented an innovative method for transporting building materials: a bridge. However, this freeway overpass is not intended for commuters or construction personnel; it is designed for the concrete itself. The Oklahoma Turnpike Authority (OTA) describes this installation over I-44 near Kellyville (west of Tulsa) as “the first of its kind on an Oklahoma turnpike.”

In a post on Facebook, the OTA reports that approximately 83,000 cubic yards of wet concrete will be transported via the conveyor bridge from the portable concrete plant located on the north side of the turnpike directly to the construction site. This method not only enhances the efficiency of concrete transport and reduces costs but also improves safety for both motorists and construction crews, according to the OTA.

Many Oklahomans might be thinking, “Haven’t I seen something like this before?” Indeed, you have. While this is a first for an Oklahoma turnpike, the first use of such a system on any Oklahoma highway took place in 2023. A concrete belt conveyor was installed over I-35 near Wynnewood (south of Oklahoma City) as part of another highway expansion project. You can watch the video below to see the conveyor bridge in operation.

Typically, the most frustrating aspect of encountering road construction is the large vehicles entering and exiting the work zone. Earthmovers aren’t exactly known for their speed either. When you want to travel from point A to point B, their slow digging and hauling seem to draw out time significantly.

By utilizing a concrete conveyor bridge, the need for concrete mixer trucks in this scenario is essentially eliminated. The OTA indicates that this could mean removing “concrete trucks from entering traffic up to 8,300 times throughout the paving operation.” One can only wonder how many minutes (or hours?) this saves for commuters.

Concrete conveyor belts are not a novel concept and certainly are not a uniform solution. Utah employed a version in 2015 that was much longer and resembled a construction project in itself. Similarly, Colorado implemented an 85-foot-long conveyor in 2018, which the Colorado DOT estimated would eliminate over 6,000 truckloads from navigating through traffic and save the 20 minutes typically required to drive between the concrete plant and the work site.

Other articles

Nico Hulkenberg confident of Sauber's progress

Nico Hulkenberg believes Sauber can make as much progress in the coming season as Haas F1 did last year.

Nico Hulkenberg confident of Sauber's progress

Nico Hulkenberg believes Sauber can make as much progress in the coming season as Haas F1 did last year.

Ferrari's tests in Barcelona continue

Ferrari's testing continues in Barcelona, with Charles Leclair and Lewis Hamilton working behind the wheel of the SF23.

Ferrari's tests in Barcelona continue

Ferrari's testing continues in Barcelona, with Charles Leclair and Lewis Hamilton working behind the wheel of the SF23.

Herbert: Russell has what it takes to be champion

Last year, former Formula 1 driver Johnny Herbert called Mercedes' results the main disappointment of the season, and now he expects surprises from the team...

Herbert: Russell has what it takes to be champion

Last year, former Formula 1 driver Johnny Herbert called Mercedes' results the main disappointment of the season, and now he expects surprises from the team...

Tsunoda: In a leadership role, I'm ready to help the team

RB racer Yuki Tsunoda believes he can handle the role of team leader in the upcoming season...

Tsunoda: In a leadership role, I'm ready to help the team

RB racer Yuki Tsunoda believes he can handle the role of team leader in the upcoming season...

FIA is set to officially approve Cadillac's entry into Formula 1.

Formula 1 | Cadillac, the potential new eleventh team in Formula 1, is set to overcome the final obstacle before receiving official approval to make its debut in 2026. (…)

FIA is set to officially approve Cadillac's entry into Formula 1.

Formula 1 | Cadillac, the potential new eleventh team in Formula 1, is set to overcome the final obstacle before receiving official approval to make its debut in 2026. (…)

Oliver Oakes: We'll support Jack Duane in anything.

Alpine F1 chief Oliver Oakes assures Jack will have the full support of...

Oliver Oakes: We'll support Jack Duane in anything.

Alpine F1 chief Oliver Oakes assures Jack will have the full support of...

This Unique Bridge is Rational in a Particular Context.

Oklahoma Turnpike employs a "first of its kind" concrete conveyor belt bridge as part of a highway expansion project.